Everything you need to know about microinverter heat dissipation

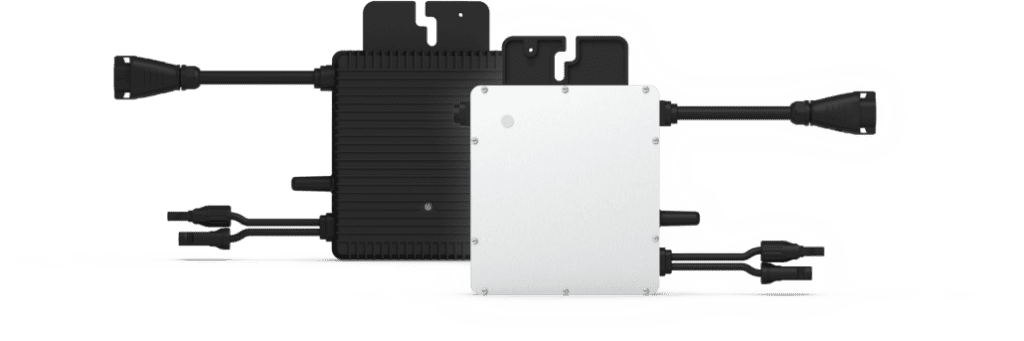

Microinverters are the cornerstone of an efficient solar PV system. By converting the direct current (DC) output of a solar panel into alternating current (AC), microinverters allow homeowners to use their solar PV system for any standard AC-powered appliance – and do so efficiently.

But in order to maintain the effectiveness of a modern microinverter, several engineering prerequisites must be met. Chief among them is adequate heat dissipation.

Source: The Hoymiles website

In this article, we’ll learn about the importance of microinverter heat dissipation and how to improve it, and discuss some of the heat dissipation techniques employed by Hoymiles to ensure your microinverter is efficient and long-lasting.

Let’s get started!

WHY IS HEAT DISSIPATION IMPORTANT?

Microinverters, like any electronic module, work best at specific temperatures. Deviations from these temperatures can cause the microinverter to underperform, leading to a loss in efficiency and, ultimately, a decrease in the overall output of the solar PV system. Even worse, they can also lead to a reduction in the microinverter’s lifespan. This is because microinverters contain sensitive electrical components, like capacitors and transistors. When subjected to high temperatures, the life span of the electrolytic capacitor decreases by a factor of two when the temperature increases by just 10 degrees more.

HOW DO MICROINVERTERS DISSIPATE EXCESS HEAT?

There are several mechanisms microinverters use to dissipate excess heat, though this depends on the brand and the specific module. Hoymiles uses state-of-the-art heat dissipation techniques to ensure strong microinverter output in a wide range of temperatures and conditions.

Heatsinks

One common method of dissipating heat is through the use of a heatsink. Aptly named, a heatsink is a passive component that absorbs and dissipates heat from a semiconductor device – it acts as an energy ‘sink’ to help control temperature.

Airflow

Another common method of dissipating heat is through the use of airflow mechanisms like ventilation. The movement of ambient air either out or across the device helps to quickly remove the heat and lower the module’s temperature.

FACTORS THAT INFLUENCE MICROINVERTER HEAT DISSIPATION

A number of key factors influence the amount of heat dissipation your microinverter can achieve.

Source: https://images.unsplash.com/photo-1589201529153-5297335c1684?ixlib=rb-1.2.1&ixid=MnwxMjA3fDB8MHxwaG90by1wYWdlfHx8fGVufDB8fHx8&auto=format&fit=crop&w=1332&q=80

Temperature and humidity

The first major factors are the temperature and humidity in which the microinverter is operating.

For example, if the microinverter is installed in direct sunlight, it will naturally be subjected to more heat than if it were installed in the shade – this will have a significant impact on its longevity, and that’s why it’s standard practice to place them beneath the panels and away from the sun’s rays.

Similarly, if your PV system is located in a hot climate, the microinverter will, of course, be subjected to more heat than if it was deployed in a cooler climate. Though warmer climates, on average, receive more sunlight (and this is obviously beneficial to a solar PV system), an ambient air temperature that is too hot reduces the efficiency of DC-to-AC conversion.

Humidity can also have an impact on microinverter function. Humid air is more difficult to move than dry air – and the added moisture interferes with internal component resistances, which can hurt the microinverter’s lifespan.

Hoymiles is well aware of this effect, and it’s why we’ve ensured all of our microinverter products are IP67-rated; when you go Hoymiles, humidity is never a problem.

Ventilation

A related factor that influences microinverter heat dissipation is ventilation. Naturally, a well-ventilated area helps to dissipate the heat generated by a microinverter array. Conversely, if the surrounding area is not well ventilated, heat will build up – especially in enclosed spaces.

Since hot air generally moves up, this also makes it prone to getting trapped in pockets underneath equipment. Depending on how your microinverters are placed or positioned, this can create a significantly hotter environment for the microinverters to operate in, which can lead to decreased performance and, in extreme cases, permanent damage.

It’s important to note that good ventilation is not just important for microinverters; it’s also important for the solar panels themselves. Similar to how microinverters lose efficiency at hotter temperatures, solar panels also absorb less energy from the sun when they’re outside of their operating range.

This is why it’s important to install your solar PV system in an area that has good airflow and, if possible, take advantage of natural breezes. Fast-moving air can disrupt the aforementioned hot pockets and keep your microinverters working at maximum efficiency.

Output power

Lastly, the output power of the microinverter is another key factor that influences heat dissipation. The more power the microinverter outputs, the more heat it generates.

That’s why microinverters with a higher output power often require better heat dissipation methods than those with a lower output power. Additionally, this has implications for reactive power control – changing the output power to help modulate the operating temperature – which we’ll discuss below.

HOW IS HEAT DISSIPATION TESTED OBJECTIVELY?

Generally speaking, there are two ways to measure the heat dissipation of a microinverter.

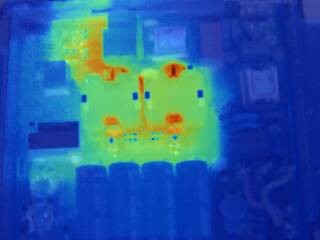

1. Thermal imaging

Thermal imaging is the process of creating a map of an object’s surface temperature. By doing so, we can see how much heat the object is emitting.

This process can be used to measure the heat dissipation of a microinverter by placing it under a controlled load and monitoring its surface temperature. The higher the surface temperature, the less effective the microinverter is at dissipating heat – and this can often be correlated with output power readings to better paint a picture of what’s going on inside.

Thermal imaging of a Hoymiles microinverter

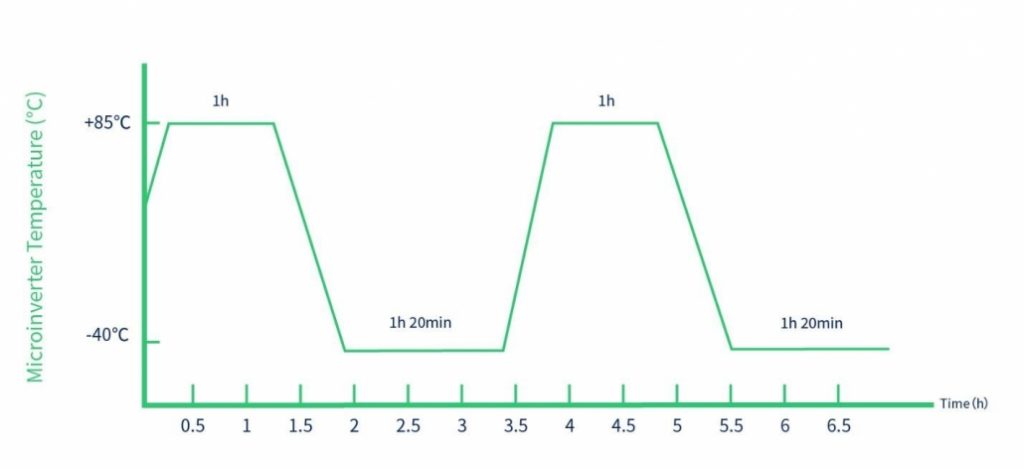

2. Thermal cycling

Thermal cycling, on the other hand, is a process whereby you repeatedly heat and cool an object in order to measure its thermal stability. By doing so, we can see how well the object handles changes in temperature and how the internal components deform or lose efficiency.

HOW HOYMILES ENSURES OPTIMAL MICROINVERTER PERFORMANCE

At Hoymiles we place a high priority on heat dissipation in our microinverters. That’s why we use several advanced methods to dissipate the heat generated by our modules.

Clever placement of the electrolytic capacitor

The crux of a microinverter’s heat reactivity occurs at the electrolytic capacitor. This component is used to store the DC energy generated by the solar panel for its later conversion into AC, and can grow quite hot during the process.

It’s also one of the most temperature-sensitive components of the microinverter, and slight changes in heat can have a dramatic impact on performance. To ensure that it functions optimally, we purposefully place it in the coolest, most well-ventilated area of our microinverters so that it can dispel heat effectively.

Temperature derating

Temperature derating is a technique that reduces the microinverter’s maximum power output as its temperature increases. Hoymiles microinverters do this gradually and reactively in order to maintain the microinverter’s overall efficiency.

When our microinverters’ temperatures reach a predefined ‘trigger’ point, their maximum power output is reduced until they fall back within the optimal operating range.

Should the heat continue to accumulate, our microinverters have a built-in ‘shutdown temperature’ at which they cease operations in order to preserve the integrity of their internal components. After a small period of time, they restart and begin converting DC into AC once more.

If you want to learn about temperature derating in depth, check out our piece here.

Temperature derating is especially important in hot climates, where the ambient air temperature can easily exceed the microinverter’s optimal operating range. By implementing temperature derating, we help ensure that our microinverters are reliable and have a long lifespan.

In-depth testing

Lastly, in order to ensure that our microinverters meet the highest standards of quality and performance, we conduct rigorous in-house testing of all of our equipment.

This includes the aforementioned thermal cycles to expose our microinverters to extreme temperature fluctuations. However, we do it in a significantly more in-depth way.

Our tests include 200 thermal cycles from -40°C (for 1h 20min) to +85°C (for 1h), which is much more punishing than the environmental conditions a microinverter would typically experience “in the field”, so to speak.

These exhaustive tests ensure that Hoymiles microinverters can withstand the most extreme environmental conditions, while still delivering peak performance.